Gaowei Group, founded in 1979, is a leading integrated manufacturer of industrial/commercial fans, smart ventilation systems, and kitchen appliances.

With strong in-house R&D and manufacturing capabilities, we deliver high-performance OEM/ODM solutions tailored to client requirements.

Our vertically integrated production, stringent quality control, and global service network ensure reliable, cost-effective solutions for ventilation and kitchen applications worldwide.

Advantages | Reasons |

Technical Expertise | · Experienced engineering team (including Master’s-level experts) driving innovation · 8 Mitsubishi CNC laser cutting machines achieving ±0.05mm precision for complex structural components |

Quality Assurance | · 12-step comprehensive inspection procedures (including X-ray inspection, airtightness testing, etc.) · SAP system ensures full traceability of material batches and process parameters for every product |

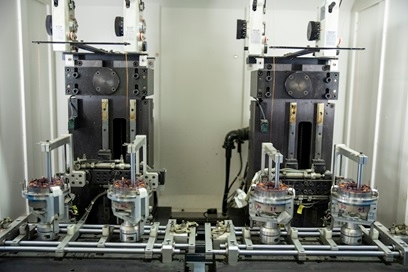

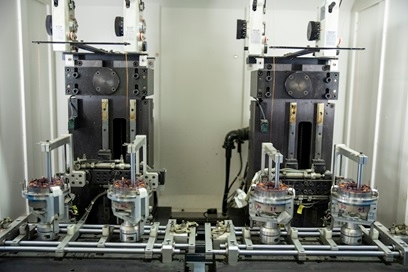

Delivery Capabilities | · 55 injection molding machines (200T to 1200T clamping force) enabling flexible small-batch production and large-scale delivery · 65 semi-automatic assembly lines with a daily output capacity of 30,000 finished units |

Cost Efficiency | · Vertically integrated 8 specialized factories, reducing outsourcing costs by 15%-22% · Smart warehouse management system minimizes material waste rate to below 0.3% |

Key Features | · Precision Metrics: ±0.05mm tolerance highlights advanced manufacturing accuracy · Quality Controls: Combines manual inspection with digital traceability · Scalability: Equipment capacity supports both niche customization and mass production · Sustainability: Low waste rate reflects lean management practices |

The safety testing projects of this testing center are authorized by Intertek&DEKRA. The laboratory has the following capabilities:

Full-scope product safety verification

Intertek Certification: Intertek is a globally recognized third-party testing and certification body, offering comprehensive services including product testing, quality assurance, and compliance verification. Products bearing Intertek certification are proven to comply with international safety, performance, and quality standards, enhancing their competitiveness and credibility in global markets.

ISO 9001 Certification: A Quality Management System standard by ISO, helping businesses enhance quality management, build customer trust, and drive continuous improvement. The certification process includes application, audit, rectification, and certification issuance. Companies need to maintain the system and undergo surveillance audits.

DEKRA Certification: DEKRA is a world-renowned third-party testing and certification authority specializing in product safety and regulatory compliance. DEKRA certification guarantees that products meet European and international market regulations, providing authoritative assurance for market access and consumer safety.

Sign NDA → Client provides technical specifications/design drafts

Engineering team conducts manufacturability analysis (±0.1mm tolerance guaranteed) Submit BOM and process roadmap within 3 working days

Mold workshop delivers rapid prototypes within 48 hours → Lab completes reliability testing (including drop, salt spray, lifespan tests)

SAP system schedules production → Feedback on production progress every 72 hours → Third-party QC full inspection before shipping

From customized solutions to tailored assistance, we are here to cater to your business needs.